5 Innovations Shaping the Future of Robotic Fabrication

The world of robotic fabrication is rapidly evolving, driven by technological breakthroughs that promise to redefine manufacturing as we know it. From enhanced precision in complex processes to increased efficiency and sustainability, robotics-based production is poised to address some of the most pressing challenges within various industries. As we look towards the future, understanding the key innovations shaping this landscape is crucial. This article delves into five of the pivotal advancements in robotics-based production that will usher in a new era of manufacturing excellence.

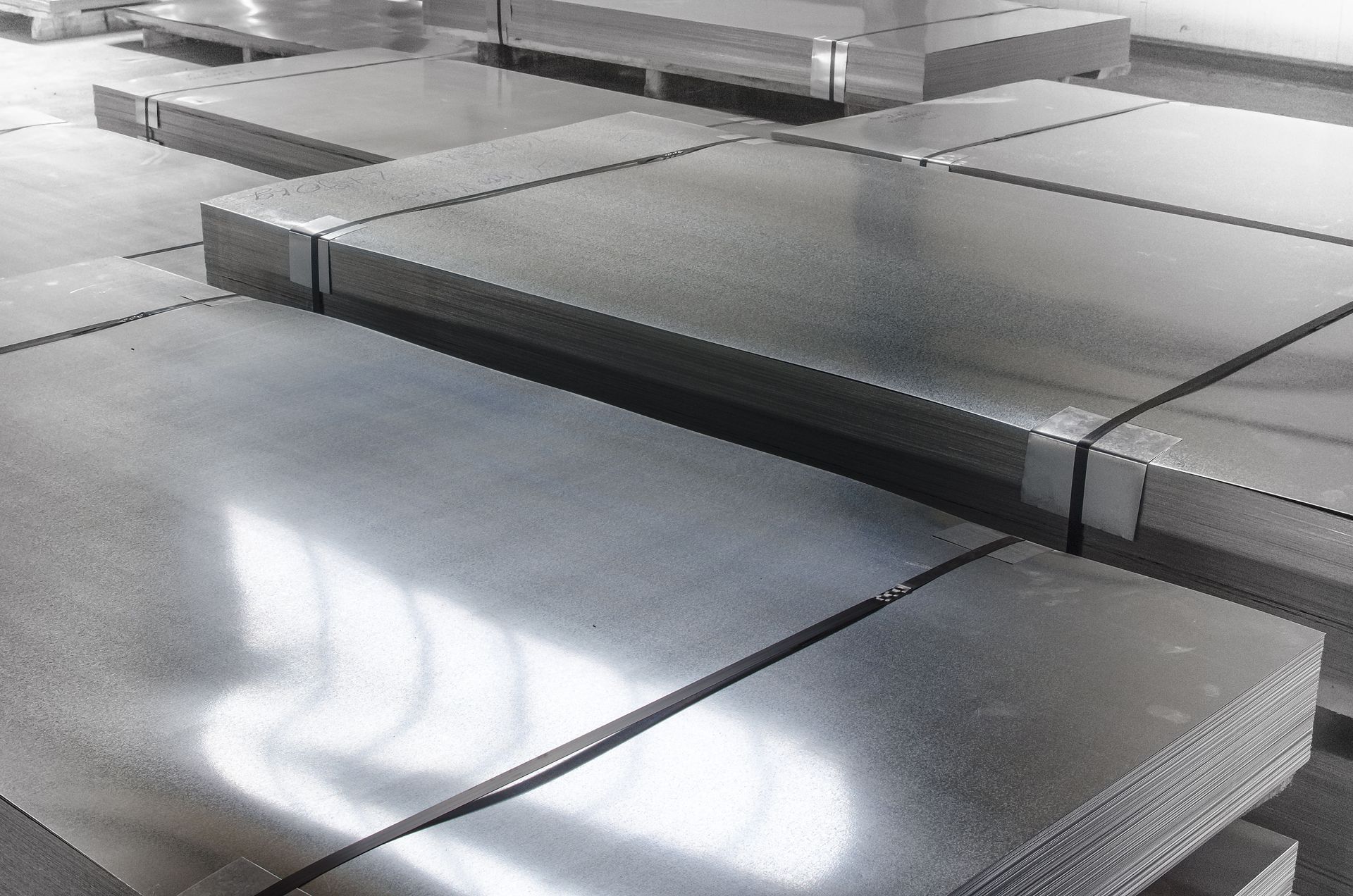

1. Automation and Robotics Shaping the Future of Manufacturing

One of the most transformative innovations in robotic fabrication is automation and robotics. The integration of these technologies is making manufacturing processes smarter and more efficient. According to BenchMarkSteel.com, automation and robotics were among the trends expected to shape the future of metal fabrication in 2024. By employing advanced robots equipped with AI-driven capabilities, industries can streamline operations through precise control, reduced human error, and an overall boost in productivity. This trend is not only enhancing speed but also enabling more complex and intricate designs that were previously infeasible.

2. Additive Manufacturing Revolutionizing Production Through 3D Printing

Another significant innovation is the rise of additive manufacturing, commonly known as 3D printing. This technology allows for the production of components layer by layer, which dramatically reduces material waste and production time. Additive manufacturing is particularly beneficial in prototyping and small-batch production, where traditional fabrication methods would be too costly or slow. Additionally, it enables more complex geometries that were previously difficult or impossible to achieve with conventional methods. As this technology matures, its integration into robotic systems is expected to become more seamless, facilitating the on-demand production of parts with unparalleled customization and precision, which further enhances overall manufacturing flexibility.

3. The Internet of Things (IoT) Enhancing Manufacturing Efficiency

The Internet of Things (IoT) is also playing a critical role in the future of robotic fabrication. IoT integration allows devices to communicate with one another, leading to more coordinated and efficient systems. By interlinking machinery and systems, manufacturers can achieve real-time monitoring and predictive maintenance, which minimizes downtime and enhances productivity. According to BenchMarkSteel.com, IoT was one of the key trends to watch in 2024, emphasizing its importance in crafting a more resilient and responsive fabrication environment in the future.

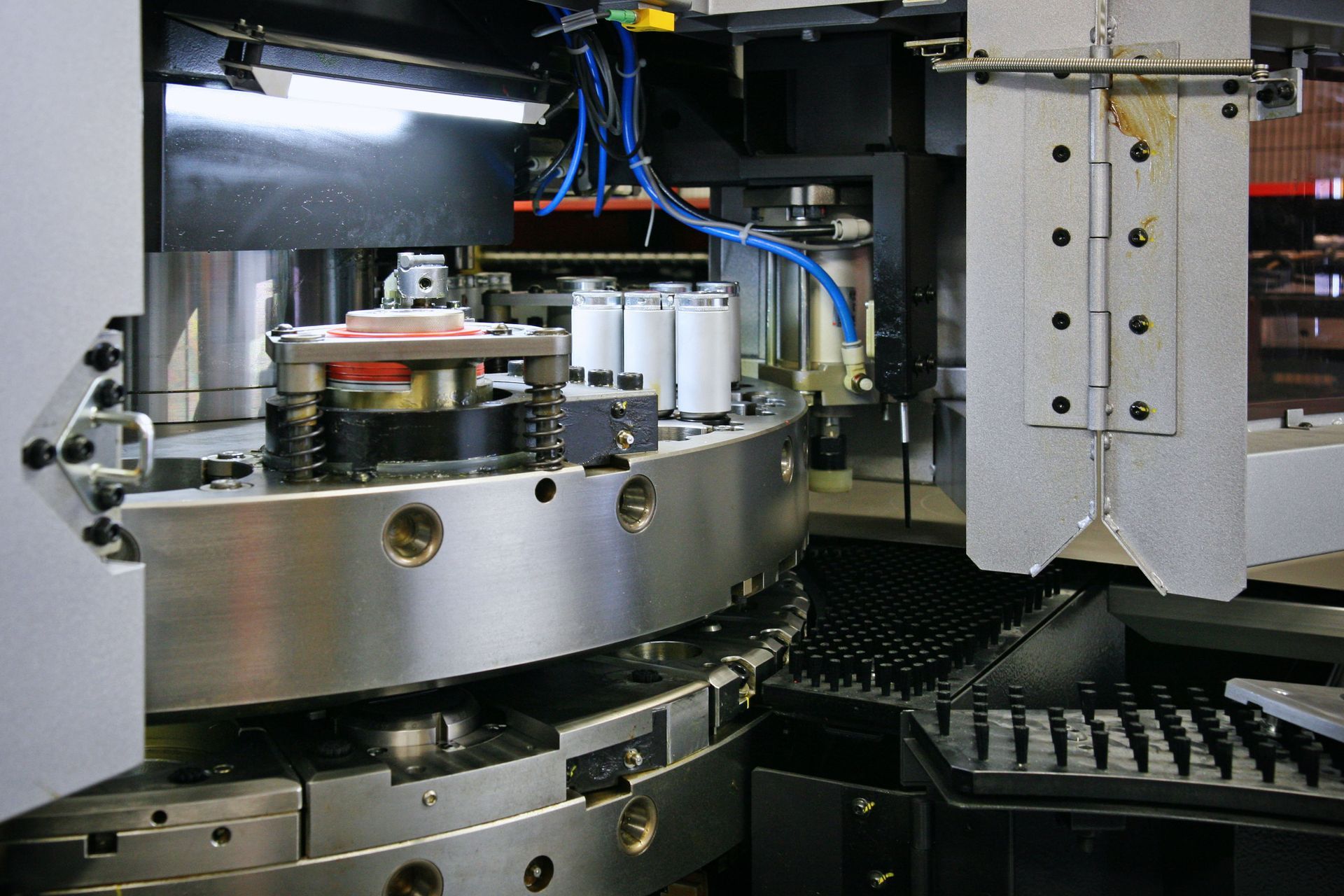

4. Artificial Intelligence Impacting Manufacturing and Quality Control

Advancements in artificial intelligence (AI) are further enhancing robotic fabrication processes. AI algorithms enable machines to learn from data and improve their operations autonomously over time, allowing them to refine their functionality with each cycle. This capability is transforming how manufacturers approach quality control and decision-making. By using AI-driven systems, manufacturers can anticipate defects before they occur and adapt swiftly to changing conditions, ensuring that production remains consistent and high-quality. The continual learning and adaptation facilitated by AI help in refining manufacturing processes, making them more robust, efficient, and capable of meeting increasingly complex demands.

5. Sustainability in Manufacturing Paving the Way for Eco-Friendly Practices

The pursuit of sustainability is driving innovation in robotic fabrication, as well. Industries are increasingly focused on reducing their environmental impact through more efficient use of resources. The integration of eco-friendly materials and energy-efficient processes within robotic systems is becoming more commonplace. Such initiatives align with global efforts to reduce the carbon footprint of manufacturing activities. As a result, companies adopting sustainable practices are not only contributing to environmental conservation but are also reaping economic benefits through cost savings and enhanced brand reputation.

The future of robotic fabrication is being sculpted by a host of cutting-edge innovations. From the power of automation and robotics to the precision of additive manufacturing and the connectivity of IoT, each advancement offers unique benefits that redefine what is possible. The integration of AI and a focus on sustainability further ensures that manufacturing processes become smarter, cleaner, and more adaptable. As these innovations continue to advance, they promise to uphold and enhance the standards of precision, efficiency, and sustainability in the world of manufacturing. As manufacturing continues to evolve, Ray-Mac, Inc is here to help you stay ahead with innovative, precision-driven solutions. Contact us today to discover how our advanced manufacturing services can enhance your production processes and drive efficiency in your business.

Share On: