A Brief Guide to Maintaining Robotic Units

In today's fast-paced industrial landscape, robotic units have become an integral part of manufacturing processes. These units, especially in fields involving robotic fabrication, offer unparalleled precision, efficiency, and productivity, making them invaluable assets across various sectors such as automotive, aerospace, and electronics manufacturing. Robotic fabrication systems are often tasked with complex, repetitive tasks that require exacting standards, so their maintenance is critical to sustaining continuous operation and minimizing costly downtime. This article explores the critical aspects of maintaining robotic units to ensure their longevity and efficiency, offering valuable insights for manufacturing managers, technicians, and robotics enthusiasts involved in robotic fabrication environments.

Prioritize Routine Maintenance for Reliable Performance

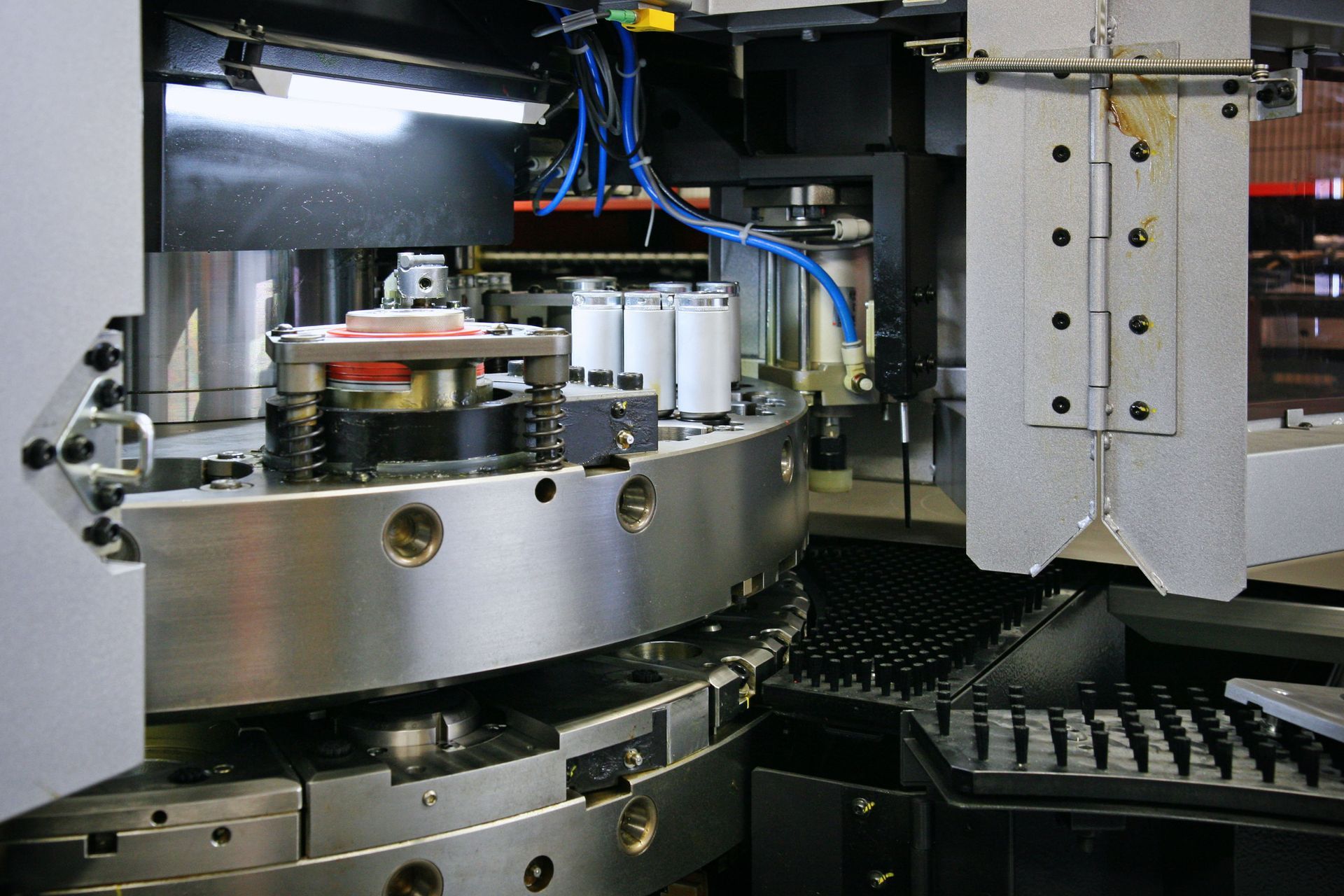

Regular maintenance is crucial for the seamless operation of robotic units used in robotic fabrication processes. Like any other sophisticated machinery, robotic fabrication equipment is subject to wear and tear from constant movement and exposure to industrial environments. Without proper and consistent maintenance, critical components such as actuators, sensors, and drive systems can degrade, causing unexpected malfunctions or complete system failures. Scheduled maintenance routines help detect these early warning signs and address them promptly, ensuring that the fabrication process maintains high precision and productivity. Moreover, regular maintenance improves safety for operators working alongside these robotic fabrication units by preventing sudden breakdowns that could pose hazards.

Establish a Preventive Maintenance Schedule

Preventive maintenance involves the strategic scheduling of inspections, testing, and servicing to avoid sudden failures that disrupt robotic fabrication workflows. A comprehensive preventive maintenance plan for robotic fabrication units typically includes routine lubrication of joints and gears to reduce friction, alignment checks of mechanical components to prevent wear, and updating control software to incorporate the latest performance and safety improvements. Integrating data analytics into preventive maintenance allows manufacturers to predict when parts might fail, enabling timely replacements before breakdowns occur. Establishing such a schedule can significantly reduce downtime and increase throughput in robotic fabrication settings. According to the International Federation of Robotics (IFR), over 4 million robotic units are currently in use worldwide, underscoring the scale and importance of systematic upkeep in industries relying heavily on robotic fabrication

Train and Empower Skilled Maintenance Personnel

The complexity of robotic technology used in robotic fabrication demands a skilled workforce capable of performing precise maintenance tasks efficiently. Investing in comprehensive training programs equips maintenance personnel with the knowledge to diagnose and repair intricate robotic systems and their software controls. As robotic fabrication technology advances rapidly, ongoing education and skill development are essential to keep technicians informed about new tools, diagnostic methods, and maintenance best practices. Well-trained personnel not only reduce the risk of human error during maintenance but also contribute to continuous improvement by identifying subtle inefficiencies or emerging issues before they escalate, thereby safeguarding the quality and consistency of robotic fabrication outputs.

Utilize Advanced Diagnostic Tools

Advanced diagnostic tools play a vital role in maintaining the health and performance of robotic fabrication units. These technologies enable technicians to conduct non-invasive assessments by collecting real-time data from sensors embedded within the robotic system. In robotic fabrication, such diagnostics leverage predictive analytics and machine learning algorithms to forecast potential failures or maintenance needs based on operating conditions and wear patterns. Early detection made possible by these tools minimizes unplanned downtime, allowing manufacturers to plan maintenance activities around production schedules. Furthermore, diagnostics improve resource allocation by pinpointing specific components requiring attention rather than performing broad, time-consuming inspections across the entire robotic fabrication system.

Document Maintenance Activities and Gather Feedback

Keeping thorough and detailed records of all maintenance activities is essential for monitoring the performance and reliability of robotic fabrication units over time. Documentation includes logs of inspections, repairs, parts replacements, and software updates, which together create a comprehensive history of each robotic unit's condition and usage. In the context of robotic fabrication, this data helps manufacturers analyze trends and identify recurring issues that may indicate design flaws or the need for improved maintenance procedures. Additionally, gathering feedback from operators and maintenance staff provides practical insights into the day-to-day challenges faced during fabrication processes, enabling continual refinement of maintenance protocols. Well-maintained documentation supports decision-making around future investments in

robotic fabrication technology and training programs.

Maintaining robotic units is an essential responsibility for any organization leveraging robotics in its operations. By committing to regular and preventive maintenance schedules, investing in employee training, and utilizing advanced diagnostic tools, companies can ensure the optimal performance and longevity of their robotic assets. As the number of robotic units in factories continues to grow globally, developing and implementing efficient maintenance practices will be paramount for organizations that wish to remain competitive and sustainable in the modern industrial arena. If you need something fabricated or want to learn more, call the team at Ray-Mac, Inc. today!

Share On: